Gidget gets a wriggle on in the Peking to Paris Rally

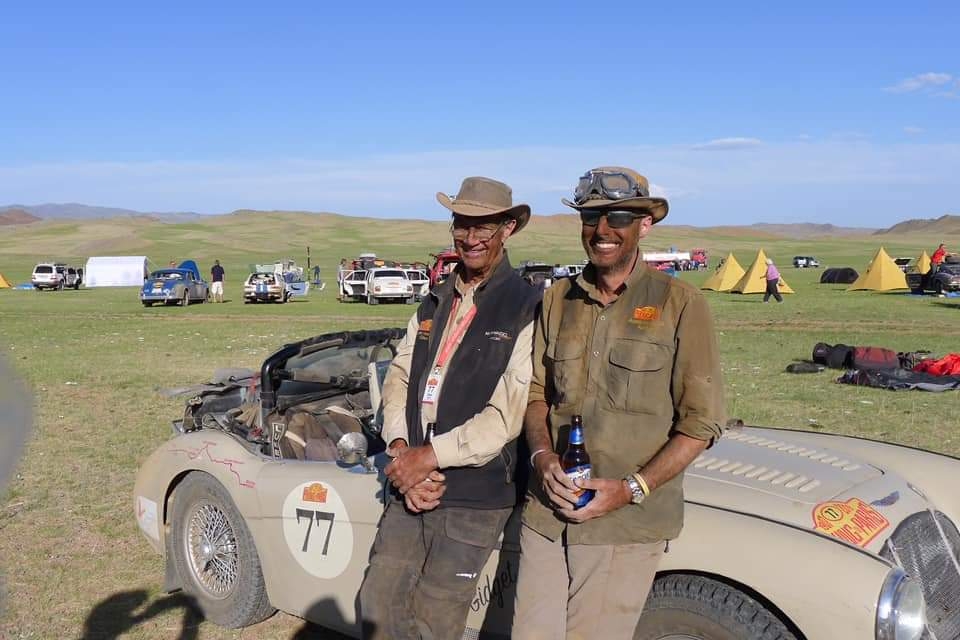

This is the story of an intrepid adventure by club member at the time Giles Cooper and Co-Driver Ashton Roskill taking a 1954 model BN1 100 Austin Healey and the modifications made to the standard car to meet the gruelling requirements of the rally. The content has been adapted from several sources by David Baggs.

THE MODIFICATIONS

Background history:

One of ~500 Coronet Cream Austin Healey 100 BN1s built to celebrate the Queen's coronation. Build date January 1954 Built for the US market - no history from there except that she started life in California Shipped to SA sometime in the early 1980's (when she was converted from LHD to RHD) She lived in SA until ~2014, when she came to Sydney Ashton bought her in 2015.

So, what did they do to her (it's a long list, and the full build is documented on Giles' blog starting here: https://austin-healeypekingtoparis2019.blogspot.com/...)? but here is a 'summary':

Three principles were adopted:

- Make her strong

- Make her lighter with more ground clearance

- Ensure she runs cool (Healey's have a reputation for running hot).

Full strip of the bodywork and all running gear off the chassis back to a bare chassis (except the bulkhead, which is welded to the chassis) Cut out and replaced all the rust and accident damage; primarily this was on driver's side, and the front cross member Gusseted and reinforced all the suspension pick-up points; boxed in the rear shock absorber mounts; welded on pick up points for the undertrays. Passenger door and sill redesigned to accomodate side-exit exhaust.

Rebuilt the car from the ground up, replacing everything. Literally everything. All the suspension parts, all bushes, all spring s replaced with Denis Welch parts (including 800lbs rally rear springs - which were hopeless - see below!)

Replaced the BN1 rear axle with a refurbished BN2 unit. The diff was rebuilt and both axles replaced with Denis Welch units; all bearings and

seals were replaced. Gearbox was replaced with a rebuilt W50 (Toyota Supra) 5-speed unit. New driveshaft was built to suit the new gearbox and axle. New floor panels welded in; new boot panels welded in; new rear bumper carriers welded in.

Gearbox cover was redesigned to allow it to be removed, so the gearbox can come out through the cabin (rather than having to take the engine out).

Front wings rebuilt (rust along the bottom edge was cut out and replaced) and vents cut in to allow hot air out. All lines were re-routed from under the car to through the cabin - fuel comes through under the navigator, electrics and brake lines under the driver.

All electrics from under the bonnet were re-designed to be on the cabin side of the bulkhead; a new wiring loom was built to accomodate a modern fuse-box and bus bar to run auxiliary services.

Engine was stripped and everything except the block was thrown away (actually, I made a lamp out of the crank!) Engine was line-bored and rebuilt using Denis Welch everything - balanced crank, harmonic balancer, alloy head, camshafts and followers, rods, pistons and all bearings. we specifically built a low compression engine (9.5:1) to cope with poor fuel; even so, running 92Ron fuel, the engine was dyno-tuned at 98hp and 180foot pounds of torque.

The sump was cut-and-shut to reduce the height, so it would fit under the bash-plate; in doing so we increased the capacity of the sump to 8L.

Distributor was rebuilt and a spare distributor head also rebuilt and adjusted to the car, then removed as a spare.

Twin H4 SU carburettors were refurbished and refitted; foam air filter fitted; ducting to direct air from front cowl fitted.

Water pump and mechanical fan were deleted and replaced with Craig Davies electric water pump and fan. Radiator was replaced with Red Devil 3-way radiator (with in-built water to oil cooler, which we never needed to use); the radiator is rubber mounted to prevent it flexing with the chassis.

Cowling was fitted to force all air through the radiator (with a seperate cowl directing fresh air to the carburettors); original grille replaced with high-flow (75%) stainless steel mesh.

Fuel system fitted as follows: replacement aluminium 40L tank fitted as per original location; additional 20L auxiliary tank fitted above 40L with gravity feed and tap to isolate; glass-bowl fuel filter with water release valve and dual SU pumps (able to be separately activated from the cabin) fitted to the inside of the rear left wheel arch, mounted on a rubber-mounted plate; rubber hosing throughout the boot, steel fuel lines from boot through cabin,

rubber hosing under the bonnet.

Cabin fitout as follows: original seats replaced with MGF Trophy seats (half-leather, half cloth), hard mounted to the floor (suit 6'1" driver and navigator); original 17" steering wheel replaced with 15 " MotoLita leather covered period wheel.

Central electrical control panel mounted on top of the gearbox cowl - this houses the following switches:

- Ignition Kill

- 2x fuel pumps

- Driving lights

- Cabin, under-bonnet and boot lights.

Also has 2x 1kg fire extinguishers mounted on top. All original dials refurbished (speedometer, tachometer, water temp and oil pressure; fuel gauge); additional oil temperature gauge added in front of navigator.

Door cards replaced with customised cards including storage space for water bottles, suncream etc. Additional arm rest built between the seats to provide discrete storage for phones, wallets etc. Original "glovebox" tray refitted under dash, with cargo netting to prevent contents bouncing around. Lightweight marine carpet fitted throughout (this doesn't absorb water, so dries quickly).

Full-length ventilated bash plate fitted; 6mm alloy from front to behind gearbox, 3mm alloy from there to rear valance, covering rear axle and fuel tank. Half-cage fitted, with rear-facing struts braced to back of the chassis; mounted to the wheel-arches with plates.

Fitted over-sized 195x85x15 tyres to gain some extra ground clearance - dry with no passengers she has 8.5inches of ground clearance to the bash plate. She weighs 850kg wet but unloaded.

So that's about it - obviously she's been run-in since then, and particularly the undertray has been well used.

The only mechanical issues we encountered on the rally were: we broke two rear springs which are now replaced with Russian-sourced, cobbled-together springs - the rolled-ends of the original springs had to be cut off and welded and riveted to the Lada springs we could get - these would (in future) benefit from being taken out and perhaps being replaced with e.g. Toyota Hilux uprated springs mud got into the bellhousing on a particularly wet and muddy stage, and destroyed the graphite clutch bearing; this would benefit from being replaced with a roller-type bearing.

We had to bypass the ignitiion switch as it got Gobi desert dust in it, and we had to adjust the points out once when we lost power in Germany, otherwise the electrics caused no problems at all.

We lost a headlight and a sidelight glass on the very rough climb on day 9 in Mongolia - they shook out; the headlights are now left-dipping Vaz headlights (fitted in Novosibirsk, and the sidelight glass is now a coke bottle).

THE RALLY: 'THE END OF THE ROAD'

By Giles Cooper.

When all is said and done, the Peking to Paris Enduro motor challenge can be broken down into 3 sections:

1) Days 1 – 18: Rough roads of China, Mongolia, and Kazakhstan

2) Days 19 – 26: The long slog across Russia

3) Days 27 – 36: Europe.

Days 1-18 are by far the toughest, and it is here that the event is won or lost. A serious breakdown or other delay in this section, and you will never catch up time lost here once you get to Europe.

Days 19-26 are just one long day after another across Russia. You still need a good reliable car, but the (slightly) smoother roads mean that you are not beating the car to pieces quite as much any longer. Finally, the run across Europe is relatively easy, as long as you still have a good car. The biggest issue is often the busy traffic!

So after over 2 years of preparation, how did Gidget perform on the rally itself? The results speak for themselves:–

• 29th overall (out of 72 cars in Classic)

• 16th in our class (over 2 litre)

• 7th outright overall in ALL timed tests

• 5th outright in the European Cup (from Finland onwards)

• And, most importantly, she made it to Paris without being towed or trucked.

After starting at the Great Wall north of Beijing on 2nd June, it was 2 long days, mostly on excellent roads, heading towards Mongolia. Once in Mongolia, the route got a lot tougher as we headed to Ulaan Bataar, but we made it there without too much mechanical drama, although we realised that we had too much weight on board with all our spares, and if we were ever going to make it to Paris, we would need to jettison some of our heavy spares.

The next 5 days after Ulaan Bataar were simply incredible. 5 nights of camping, and on several of the days we didn't see any tarmac roads at all, and even required fuel to be delivered to the camps by tanker because we passed no fuel stations during the day! This required us to be able to travel all day without refueling, which, with our 30-litre auxiliary tank added to our 45-litre main tank, was achieved. However the rough roads took their toll in other ways – on day 6, out from Ulaan Bataar, we hit some very rough roads, which eventually broke our right rear leaf spring. Luckily one of the sweep mechanics was nearby, and we got it fixed well enough so we could limp into camp, where one of our spare main springs (which we had mounted in place of our bumpers) was fitted during the evening.

Day 9 saw some terrible weather as we climbed rocky mountain trails to almost 3000 metres, the combination causing many cars major problems. We only made it to the top of the mountain by traversing backwards and forwards across the side of the hill, as we simply didn't have enough power to go straight up the hill. But many other cars who were going to eventually beat us in the overall results did have to be towed up the hill. We are proud to say that, unlike many others, Gidget was never towed or trucked once during the entire event. She covered it all under her own steam. However, the traversing meant that we were off the already rocky trail, and were picking a path between larger rocks, all the time unable to slow down too much in case we didn't make it to the top. But we made it to camp, which that night was beside the shores of the scenic Achit Lake, only to find there were millions of flying insects sharing our campsite. Fortunately, they were not the biting kind, just extremely annoying!

After a very long border crossing out of Mongolia into Russia, with many broken cars having to be pushed or towed across, we drove a surprisingly scenic road through the Altai mountains. However, the last 60km into camp were again off-road, and very rough and rocky, and not long after the start of the dirt, we broke yet another rear leaf spring. Fortunately, Ashton had learned how to fix it from our previous breakage, and once duly rigged, we limped to camp that way, thus incurring considerable time penalties, but ensuring that we kept going. Once in camp, our second spare leaf was fitted by the mechanics. We no longer had any spare springs, so we had to drive with care until we could get something better made up.

The long 550km Day 11 saw us battling clouds of hatching butterflies in the forests, and coping with big crowds of enthusiastic people every time we stopped. At the end of the day, we had to get a local welder to fix some cracks that had appeared in the rear chassis, and for the next couple of days, we drove in "preservation" mode, avoiding most of the rough special stages despite incurring big penalties. The target was now very definitely "to reach Paris at all costs". This approach was being taken by an increasing number of competitors as their cars continued to show signs of wear and tear from the extreme conditions being encountered every day.

We finally made it into Novosibirsk on Day 14, and a (misleadingly named) Rest Day, which would allow us time to fix the rear springs and some of the other issues encountered. New main leaves were manufactured using a much thicker leaf (from a truck?) cut to length, and then the eyes from our current springs were cut off and welded and riveted onto the ends of these new leaves. Fingers crossed, but they certainly gave us a little more ride height, reducing the rubbing of the tyres on the inner guards every time we hit a bump. While in the workshop, we also straightened out our 6mm undertray with a sledgehammer, replaced a headlight we had lost somewhere on the road (with a unit from a Lada), and re-tapped the gearbox steady bolts which had also come loose.

Day 15 saw the weather turn very wet and cold, and after a stop in a village to help the locals celebrate the start of Spring, we were set loose on a VERY wet, muddy, and slippery timed stage, and advised by the organisers "to be careful". Unfortunately, the wet mud got into the electrics, requiring repeated stops to dry them out, but we eventually made it to the time control. With both us and the car filthy and wet, we then crossed the border into Kazakhstan, eventually reaching Astana where Gidget (and us) got washed, and we fitted a rubber glove over the distributor to help keep future moisture out, perhaps a day or two too late!

Shortly after leaving Astana, we had clutch problems, and after trying to adjust it, realised the issue was more serious, and despite having fitted a new assembly prior to the start, the abrasive mud from 2 days ago had basically destroyed the throw-out bearing,

leaving Ashton unable to de-clutch. 12 or so other cars had similar issues after the same muddy stage, and this necessitated push-starts, extreme measures when driving in traffic, and extensive overseas phone calls to locate spare parts and eventually get them hand delivered to Ufa, the next Rest Day 3 days away. In the meantime, we avoided some of the rougher timed stages, and generally drove as required to enable us to reach Ufa intact.

Finally we reached Ufa, and many cars underwent extensive repairs after the last 18 days of stunning yet destructive roads across some of the most desolate scenery in the world.

Upon removal, there was little left of our throw-out bearing, and Ashton toiled all day to get the replacement parts installed. On the way home from the workshop, an electrical problem left him briefly stranded, but

seemed to resolve itself, and was forgotten. We had Russia to cross – 4 days of non-stop long-distance driving to St Petersburg.

Shortly after leaving Ufa, the electrical issue resurfaced, and this time did not correct itself. Unable to locate our bag containing circuit testers, we were struggling to resolve the problem until Doug & Mike McWilliams stopped to help and eventually found the (original Lucas) ignition switch was at fault! Since this was not actually required due to our revised wiring, we short-circuited around it and eventually were on our way, albeit once again behind time. This was compounded by a navigational error when we went 50km east instead of west, but eventually we got back on track both location and time wise, and completed a lap of the Kazan Ring race track for one of the stages.

The remaining days to our final rest day in St Petersburg were long (600km) sections, and en route our starter motor also decided to pack up – another gremlin from that very muddy stage, but probably compounded by the clutchless starts made using the starter motor to get us moving. Ashton managed to fix this in St Petersburg, and the following day we finally headed into Finland and Europe proper. Delightful scenery, and incredible forest stages. They know how to enjoy their motorsport in Finland!

An easy day was then spent mostly on the ferry across to Estonia, before we headed down through the Baltic States, with several special stages on local tracks, where Ashton was able to have some fun now he had both a clutch and a starter motor! Three days through Poland, with ongoing special stages, plus, when we were stopped by a local policeman for going a little too fast through his village, he made the comment that "He had never stopped an Australian car for speeding before", and after a few apologies and promises to never speed again, we were allowed to leave with our wallets intact!

Eventually into Germany, and the traffic on our route was insane, which, when added to the increasing summer temperatures, made for some trying days. A visit to Wolfsburg was interspersed with visits to circuits for timed tests, and in between we had to fix both another electrical problem (when the distributor points stopped opening) and then a loose banjo on the bottom of a carb that pumped fuel out extensively before we fixed it.

Then it was on into Belgium, with spirited and complicated Tulip map runs through the scenic back roads of the Flanders Fields, all the time urged on by increasingly large crowds who come out to

cheer us on. On reaching Ypres on our last night on the road, not only were the crowds in the car park beside the Cathedral enormous, but we were also welcomed by Phillipe Deckers from the Belgian Austin Healey Club. The atmosphere was certainly becoming more relaxed as we neared Paris, and the realisation was finally setting in that we may just reach the end successfully.

Day 36, our last day, saw an almost parade drive in through France to Paris, however Paris kept one last test for us all – heavy traffic and high temperatures meant that both crews and cars suffered, and the delays getting into Place Vendôme put a bit of a damper on the finish. However, we got there fairly early, and some 20 or more family and friends were there to greet us both, although to be honest everything was somewhat of a blur as we struggled to just "stop" after 36 continuous days of competition across some of the roughest terrain in the world, plus of course, over 2 years of non stop car preparation to get us to the start line. We, and Gidget, had made it to Paris.

The cars were collected by truck that evening while we were at our Prize giving dinner, and were shipped back to their various destinations around the world, with ours arriving in Australia in early September. After some 10 days of delays we picked her up from the port where, surprisingly (considering a totally flat battery after the shippers had left ignition switches on), she started almost straight away (with a little help from an extra battery), and was able to be driven home.

An Austin Healey had made it from Paris to Peking, despite many people's doubts. The Great Adventure was over. But the memories will last a lifetime.

"It felt good to drive into Paris on day 36, even if the traffic was terrible. Thank you to everyone who followed us - it provided the extra impetus to complete this amazing adventure. We drove every kilometre of the rally, Gidget only stopped three times, all electrical and all solved, we drove some places that cars really aren't meant to go, crossed 12 countries, covered 14,000 kilometres and shared it all with some wonderful people who have become close friends - thank you all!"

Ashton and Giles were also raising money for both Beyond Blue and the Cancer Council, charities dear to the hearts of both, with friends who have suffered, and Giles being a survivor of throat cancer.

Photographic credits: The page 'Hero Image' and images 3 and 5 were taken by Gerard Brown Photography. The remainder are credited to or provided by Giles Cooper.

Photo of Giles Cooper presenting to the AHOCQ Club meeting: David Baggs

Related pages